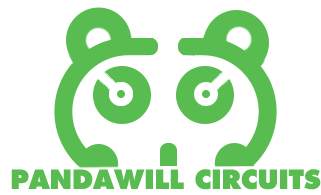

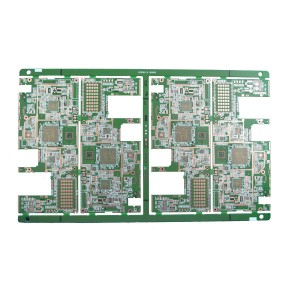

22 oyi akwa HDI PCB maka agha & agbachitere

Nkọwa ngwaahịa

| N'ígwé | 22 n'ígwé |

| Ọkpụrụkpụ Board | 3.0MM |

| Ihe onwunwe | Rogers 4350B |

| Ọla kọpa | 1 OZ (35um) |

| Elu rụchaa | (ENIG) Imikpu gold |

| Min Oghere (mm) | 0.25mm |

| Via teknụzụ | Via plugged na resin |

| Min Line Obosara (mm) | 0.10mm (4 ọnwa) |

| Min Line Ohere (mm) | 0.10mm (4 ọnwa) |

| Nkpuchi Solder | Agba akwụkwọ ndụ |

| Agba agba | Na-acha ọcha |

| Impedance | Single impedance & iche impedance |

| Mbukota | Anti-static akpa |

| E-ule | Na-efegharị nyocha ma ọ bụ ihe ndozi |

| Standardkpụrụ nnabata | IPC-A-600H Klas 2 |

| Ngwa | Military & agbachitere |

1. Okwu mmalite

HDI na-anọchite anya Njikọ Njikọ Dị Elu. A na-akpọ bọọdụ sekit nke nwere nnukwu wiwi dị elu kwa mpaghara ọ bụla na-abụghị osisi a na-akpọ HDI PCB. Ndị HDI PCB nwere oghere dị mma na ahịrị, obere vias na padị pọdụl na njikọ mpe mpe akwa dị elu. Ọ na-enye aka n'ịkwalite arụmọrụ eletriki na mbenata na ibu na nha nke akụrụngwa ahụ. HDI PCB bụ mma nhọrọ maka elu-oyi akwa ọnụ na oké ọnụ laminated mbadamba.

Key HDI Uru

Dị ka onye na-azụ ahịa chọrọ mgbanwe, yabụ teknụzụ ga-agbanwe. Site n'iji teknụzụ HDI, ndị na-ese ihe nwere nhọrọ ka etinye ihe ndị ọzọ n'akụkụ abụọ nke raw PCB. Otutu site na usoro, tinyere site na pad na ikpu site na teknụzụ, na-enye ndị na-emepụta PCB ala na ụlọ ohere itinye ihe ndị pere mpe ọbụna karị. Mbelata nke nha na ụda na-enye ohere ka ọtụtụ I / O na obere jiometrị. Nke a pụtara ịnyefe akara ngwa ngwa na mbelata dị ukwuu na mgbaàmà mgbaàmà na igbu oge ịgafe.

Teknụzụ na HDI PCB

- Kpuru ìsì site na: ackpọtụrụ nke elu oyi akwa na-agwụ na oyi akwa dị n'ime

- Liri Via: Site-onu ke isi n'ígwé

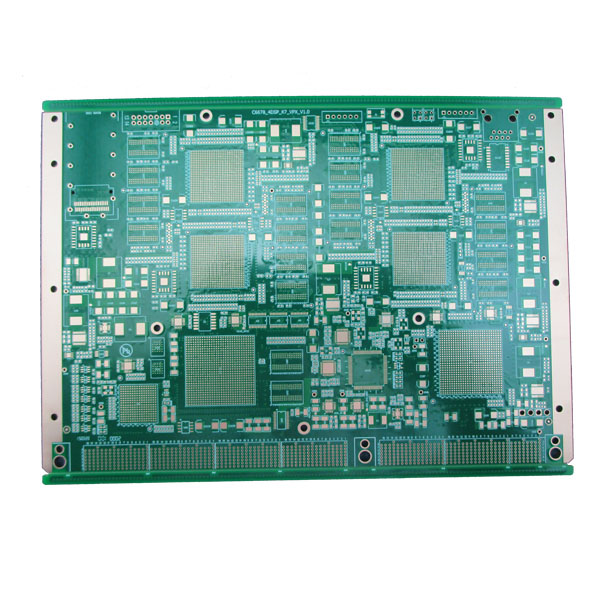

- Microvia: Blind Via (coll. Nwekwara site) na dayameta ≤ 0.15mm

- SBU (Sequential Mee-Up): Sequential oyi akwa buildup na ọ dịkarịa ala abụọ pịa arụmọrụ on multilayer PCBs

- SSBU (Nwee Ọganihu Nke Ọma): Presspị nrụpụta nke ule na teknụzụ SBU

Via na Kedo akwa

N'ike mmụọ site na teknụzụ ugwu dị elu site na ngwụsị afọ ndị 1980 emeela ka njedebe ya na BGA, COB na CSP banye obere sentimita asatọ. The via na mpe mpe akwa usoro-enye ohere maka vias-enịm n'ime elu nke ewepụghị ala. The via na-plated ma jupụta ma conductive ma ọ bụ ndị na-abụghị conductive epoxy ahụ capped na plated n'elu, na-eme ka ọ fọrọ nke nta-adịghị ahụ anya.

Da dị mfe ma enwere nkezi nke usoro asatọ ọzọ iji mezue usoro a pụrụ iche. Ọpụrụiche akụrụngwa na zụrụ technicians eso usoro anya iji nweta zuru okè zoro via.

Via Dejupụta Tydị

E nwere ọtụtụ dị iche iche nke via jupụta ihe: na-abụghị conductive epoxy, conductive epoxy, ọla kọpa jupụtara, ọlaọcha jupụta na electrochemical plating. Ihe ndị a niile na-ebute site na lie ya n'ime ala dị larịị nke ga-ere ahịa kpamkpam dị ka ala nkịtị. Vias na microvias na-gbapuru, kpuru ìsì ma ọ bụ lie, jupụta mgbe ahụ plated ma zoo n'okpuru ala SMT. Nhazi vias nke ụdị a chọrọ akụrụngwa pụrụ iche ma na-ewe oge. The multiple malite ịgba cycles na-achịkwa omimi mkpọpu ala na-agbakwunye iji hazie oge.

Teknụzụ Laser Drill

Illinggba obere ihe micro-vias na-enye ohere maka teknụzụ ndị ọzọ n’elu ụlọ. N'iji mpempe ọkụ nke 20 microns (1 Mil) na dayameta, nnukwu mmetụta a dị elu nwere ike belata site na igwe na iko na-ekepụta obere oghere. Ọhụrụ ngwaahịa adị dị ka edo iko ihe ndị na-a ala ọnwụ laminate na ala dielectric mgbe nile. Ihe ndị a nwere nguzogide ọkụ dị elu maka nzukọ na-enweghị ndu ma kwe ka obere oghere mee ihe.

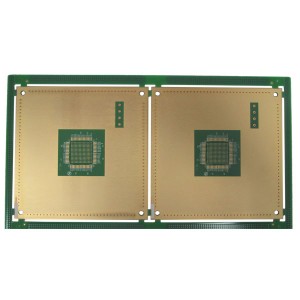

Lamination & Akụrụngwa N'ihi HDI Boards

Advanced multilayer technology na-enye ohere maka ndị na-emepụta ka sequentially tinye ọzọ ụzọ nke n'ígwé na-etolite a multilayer PCB. Ojiji nke nkedo laser iji mepụta oghere na akwa dị n'ime ya na-enye ohere maka ịcha, imaging na etching tupu ịpị. A maara usoro a gbakwunyere dị ka usoro usoro. Ationgha SBU na-eji vias juputara na-enye ohere maka njikwa njikwa dị mma, njikọta siri ike karị na ịbawanye ntụkwasị obi nke ụlọ.

Emepụtara resin a na-ete ọla kọpa iji nyere aka na enweghị oghere oghere, oge ịkụ ogologo oge ma nye ohere maka PCB ndị pere mpe. RCC nwere profaịlụ nke dị ala na nke dị larịị nke jikọtara ya na nodules dị ala n'elu. A na-eji ihe eji ọgwụ eme ihe na nke ọma maka usoro kachasị mma na nke kachasị mma na teknụzụ nke oghere.

Ngwa nke iguzogide akọrọ na laminate ka na-eji kpụ ọkụ n'ọnụ mpịakọta usoro itinye iguzogide isi ihe. Usoro nkà na ụzụ ochie a, a na-atụ aro ya ugbu a ka ọ preheat ihe a chọrọ okpomọkụ tupu usoro lamination maka mbadamba sekit HDI. The preheating nke ihe na-enye ohere ka mma a otu ebe ngwa nke akọrọ iguzo elu nke laminate, Anam Udeme obere okpomọkụ n'ebe na-ekpo ọkụ na-apụta na-ekwe ka agbanwe agbanwe mụ ụzọ ọpụpụ okpomọkụ nke laminated ngwaahịa. Entrancezọ mbata na ụzọ ọpụpụ na-agbanwe agbanwe na-eduga obere njigide ikuku n'okpuru ihe nkiri ahụ; nke a dị oke mkpa na mmeputakwa nke ezi edoghi na spacing.